The concept of shortening the distance between supplier and plate is not a new one, but what does it look like when a business ultimately cuts out the middle man? Baking Business talks to a few bakeries to hear what it looks like if you grow, produce or even raise the products you work with.

In the past few decades food trends have come and gone, but one in particular has remained staunchly popular. Paddock to plate – also called farm to fork – gained traction in the 2010s in Australia, popularised by the idea of superior ingredients that were often produced using more sustainable methods, as well as environmental reasons like reduced food miles. The end result? Higher quality products.

Wagyu beef cattle at The Artisan Farmer

Crafting the perfect filling

For Peter Doyle from The Artisan Farmer, the decision was 30 years in the making.

The paddock to plate farm, located in Nabiac, New South Wales, raises wagyu beef cattle onsite with the meat then used in both their onsite bakery and deli.

“We’ve been breeding wagyu beef cattle for almost 30 years and it was always the plan to do paddock to plate,” he said.

“One of the major benefits is the self satisfaction in knowing that the animals we’re producing are being enjoyed by our customer base. Our customers love the whole concept of the beef being grown on the property.”

Peter said the entire process took at least four years between pregnancy and producing a steer, with the cattle being processed at about 30 months of age.

After their meat has been processed in their in-house butchery, often being used to make jerky and smoked brisket, it is then handed over to the bakers who use it make sausage rolls and pies in addition to hot brisket sandwiches featuring house-made bread.

However, Peter said despite the move being a significant drawcard for their business, he was firm this wasn’t a decision to be jumped into lightly.

“There’s a lot of planning and timing that goes into this. It’s not something you can just jump into and do tomorrow, that’s for sure,” he said.

“It’s really playing the long game.”

Sherwood Park Orchard grows apples onsite

Growing your own

Taking your time before jumping in is an idea that Tara Cheesewright from Sherwood Orchard Park echoes.

The apple and cherry orchard in West Gippsland has been established for more than 100 years, and now is home to an onsite bakery and café. It is here that customers can tuck into a traditional and homey bakery range the prominently features the apples grown just metres away.

“People love to know where their food comes from… People just want to go back to basics, but these days it’s hard. Everyone is busy and it’s convenient to get things from a supermarket,” Tara said.

“We have a unique set up here because we have the bakery-café, and we can use things on our farm in our shop. But there are challenges that come with growing fruit.”

Included in this is unpredictable weather, which in recent years has seen Sherwood Orchard Park be hit by a massive hailstorm, heavily impacting their crops.

“Apples are pretty hardy, so we didn’t lose our entire crop, but they were knocked around a bit. But the beauty is we advertised them as hail-damaged and they were still edible, they just didn’t present the way that supermarkets present apples,” Tara said.

Seasonality also plays a role, particularly when your produce is regularly used in-house.

Tara said the Sherwood Orchard Park apples regularly found their way onto the bakery shelves in products like apple crumble slice, apple and caramel scones, and an apple slice. However, as apples are harvested once a year in autumn Sherwood Orchard Park does have to turn towards other local growers to ensure their bakery range is available year-round.

“Apples aren’t available year-round. We get to the end of the season and, to be honest, we’re exhausted. But there are two other local growers that we deal with in Gippsland who are operating on a different level,” she said.

“We can use their apples year-round and, because we know where they’re from and their ethics, we’re happy to do that.”

Honey produced onsite is then used across the bakery and patisserie menus

Feeling the buzz

A unique partnership between Rooftop Bees and luxury hotels Sheraton Grand Sydney Hyde Park and Shangri-La Sydney has seen beehives installed on each of their rooftops. What’s more, this honey finds its way into each of the kitchens where it is used across both their patisserie and restaurant menus.

Shangri-La executive chef Brent Morley said the introduction of the beehives had proved to be an incredible and inspiring journey for the culinary team.

“The honey we harvest shapes our menus across the hotel. Each department finds a unique way to incorporate it,” he said.

“This partnership [with Rooftop Bees] has gone beyond just honey. It’s become a shared philosophy of sustainability and creativity. John and his team at Rooftop Bees have been outstanding partners, and their support has helped us integrate local honey into the very fabric of our offerings.”

Brent said as a result of this partnership, Shangri-La no longer need to source any other honey through its purchasing system.

“If you’re enjoying honey at Shangri-La Sydney, it came from our very own rooftop,” he said.

“One standout menu item is our Signature Shangri-La Honey Cheesecake, made with an Anzac biscuit base. We enhance this cultural classic with our aromatic local honey.”

There are numerous positives associated with producing their own honey onsite, with Brent noting this even came down to a change in aromas to reflect both the changing seasons and local flora.

Additionally, full transparency in knowing where the honey was sourced from came with unmatched freshness and traceability. However, time and effort did have to be dedicated to educating both the team and customers about the “why” behind their decision.

“Then there is also the time and care involved. It’s easier to purchase mass-produced honey, but we believe the rewards of education, sustainability and storytelling far outweigh the convenience,” Brent said.

Sheraton Grand Sydney Hyde Park executive assistant manager – food and beverage Duncan Morrison agreed with this, saying that they could produce up to 50kg of annually from their own rooftop beehives.

“While our bees contribute a significant amount, the hotel serves more than 100kg of honey annually. To meet demand we also use honey from other Rooftop Bees locations, ensuring consistency in quality and supply,” he said.

“The honey features prominently in our bakery and patisserie creations, at the breakfast bar, in our in-room amenities, and in cocktails at the bar. This integration of homegrown honey reflects our commitment to sustainability while delivering a unique and memorable guest experience.”

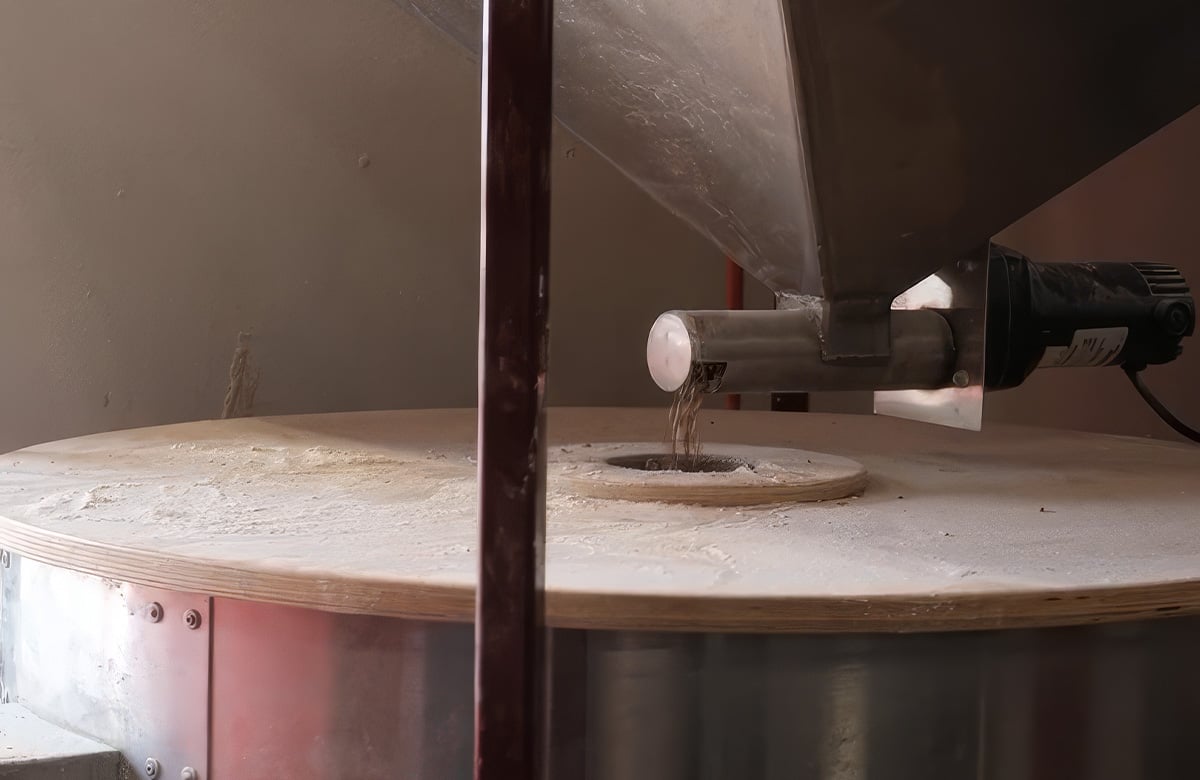

A.P. Bakery mills its own grains

Grind your own

It’s no secret ingredient quality control is high on the list for bakery owners. Ensuring you have access to superior flour only heightens the quality of the end product.

For A.P Bakery director Dougal Muffet he decided to take matters into his own hands and not only mill grains onsite, but also play an active role in growing them.

Dougal said this interest came from his childhood home on a wheat farm.

“My parents were third generation wheat farmers so I always had an interest in it and the whole process from sowing to the season to the variety,” he said.

As his career took him from chef to a baker, and Dougal said his interest in wheat and flour remained, and it didn’t take him long to realise that it all well and good being able to source high quality grain, but if you don’t have a mill to pulverize it and make flour then you can still be limited when it comes to the end result.

“I bought a new American stone mill that was one of the first pieces of equipment I bought for the bakery. I bought it before I bought an oven,” he said.

Covid brought with it the opportunity to spend time with his parents on the farm where they grew a lot of seed stock that was then used in A.P Bakery, however these days Dougal says they have returned to sourcing the majority of the grain through suppliers known for superior product quality.

“We go through close to a ton a week of grain that we mill ourselves for whole wheat. Logistically managing that and storing it and trying to grow it and keep the weevils out of it and get it to Sydney is a real nightmare. Sometimes you’ve got to be pragmatic,” he said.

“Milling grain yourself has definitely got its challenges but it’s something I think gives us a bit more room to play creatively. And we’re not just milling wheat. We mill other cereals like buckwheat… and we mill different spices.

“There are more variables with the product that we mill ourselves, but I feel we’re more attuned to it. We’re analysing the mix more and we’re looking at the bake and being more reflective of what it is because we’ve got that ownership of the product we’re putting in there. It makes our lives a bit harder, but we’re better bakers for it.”

COMMENTS